| National free service hotline 137-0622-7963 Telephone:0512-58140198 Fax:0512-58299151 mailbox:jzh@dhjx.com.cn Website:www.cube999.com Foreign trade department: Mrs yu: 15150256382 Mail:keith@junmachina.com |

| address: No. 80, Zhangjiagang City, Jiangsu City Road, No. |

Water tank drawing machine working principle water tank drawing machine is composed of a plurality of drawing head small continuous production equipment, step by step drawing, and the drawing head arranged in the water tank, the wire to the desired specifications. On the domestic several major water tank drawing machine manufacturers, the general configuration of the 20 or so of the drawing head. Through the drawing of each level, the wire diameter changes, so the working line speed of each drawing should also be changed. During the whole drawing process, only 1 motors are required to be driven by a mechanical drive or a gear box. Water tank drawing machine according to the different configuration of the die head, each drawing drawing speed is changed. Drawing speed is every moment through the die base wire flow volume, that is to make the type establishment

D2v1 = Pi Pi d2v2

The diameter of the wire in the D

V1 - line speed of wire feeding

D - diameter of outgoing wire

V2 - line speed of outgoing wire

The working speed of the drawing head of the water tank drawing machine is based on the above formula, which ensures the synchronous operation of each drawing head. The drawing process of water tank drawing machine completely through the mechanical axis drawing completed, and the mechanical axis is in the same drive spindle, so the tension at all levels of the system depend on the speed of different line and tension wheel to control the synchronous coordination.

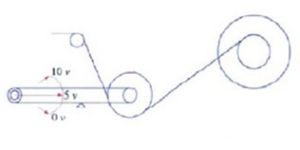

Cooling fluid is needed to heat the work. The take-up part with 1 small power motor, need to keep the line winding tension keep constant, if this period of tension fluctuation, winding line on the spool roll will be uneven. The sketch map of the drawing is shown in Figure 1.

Figure 1 water tank drawing machine of Tutu 1 water tank drawing machine diagram

The coiling part of the water tank drawing machine is the key link in the control system of the equipment, which also directly affects the quality of the steel wire. For the collection, there are usually two control methods:

1) the tension roller is used to adjust, and the tension of the winding is guaranteed by the tension roller itself.

2) using torque control, the tension of the winding is determined by the size of the torque, but it will lead to the uneven winding tension because of the change of the winding diameter.

For the process of higher requirements of the water tank drawing machine, usually using the first control mode, the use of inverter PID ACS510 correction function to control the tension roll.