| National free service hotline 137-0622-7963 Telephone:0512-58140198 Fax:0512-58299151 mailbox:jzh@dhjx.com.cn Website:www.cube999.com Foreign trade department: Mrs yu: 15150256382 Mail:keith@junmachina.com |

| address: No. 80, Zhangjiagang City, Jiangsu City Road, No. |

1, the staff should be strictly in accordance with the operating procedures for operation.

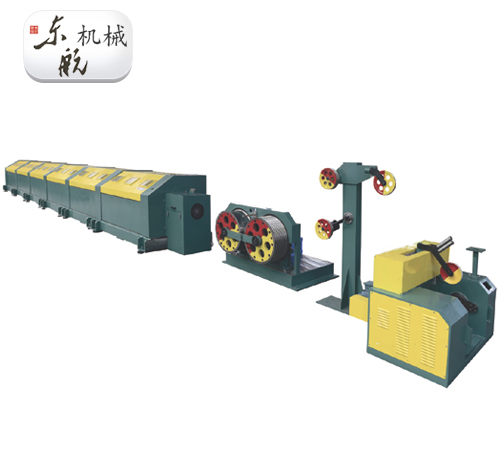

2, each boot before the wire drawing machine equipment for safety inspection, water tank drawing machine and then according to the lubrication chart requires timing, fixed point, quantitative and lubricating oil, oil should be clean without precipitation.

3, wire drawing machine must always keep clean, not part of the anti rust paint. Lubrication wiredrawing machine motor bearing overflow oil should be changed regularly filling, and regularly check the electrical part of the work is normal and safe.

4, regular inspection of the triangle belt, handle, knob, keys are damaged, serious wear should be replaced in a timely manner, and to supplement the spare parts.

5, regularly check the repair switch, insurance, handle, to ensure that the work is reliable. 10 minutes before work every day, for wire drawing machine lubrication and cleaning cleaning wire drawing machine.

6, is strictly prohibited non designated personnel operating the equipment, usually must be done away from the machine.

7, wire drawing machine after retaining the NC material position controller positioning control. The system can control the running speed of the ordinary three-phase asynchronous motor, using the high resolution photoelectric encoder to directly detect the moving parts, which can accurately position the rear stopper.

8, because it is an ordinary three-phase asynchronous motor control, and stepper motor, servo motor, variable frequency speed control system, to maximize the cost savings of the whole after the control system of the control system. The system is easy to operate, high precision, strong anti-interference ability, applied to plate shearing machine, bending machine after the block system, is a cost-effective control solutions.

9, wire drawing machine on the requirements of the inverter inverter 0.5HZ up to 150% starting torque. The output frequency can be adjusted automatically with the change of load and voltage. Requirements to achieve a number of proportional transportation control. Must have the RS485 communication function and the PLCPC machine realizes the communication control. Good power saving effect. 4 using the common DC bus mode control. Aggressive use of V/F control or space vector control inverter fault torque is not enough. Conservative V/F converter appears low frequency. Will occur when the speed is not stable phenomenon, when the polishing machine load and voltage changes. Therefore, it can not be high precision ratio linkage control, only the sense of vector control to control the motor's slip.

10, while in the load for the motor characteristics, the wire drawing machine running in the process of constant motor and generator load characteristics. The motor slip is positive, and varies with the change of the load; on the other hand, when the load characteristic of the generator, the motor slip is negative, easy to exceed synchronous speed, the negative planting and characteristic of the generator in proportion to the size, therefore not high accuracy ratio of linkage control.